Established Since 2010

Dong Luc™ is the leading CaCo3 filler masterbatch manufacturer and world-class plastic additive supplier. Located in Vietnam, less than 7 km from the Hai Phong port, Dong Luc™ is in a prime location for the lowest import and export costs, and the fastest transportation times.With our team of professional engineers and experienced technicians, we are committed to developing the greatest value added solutions for our customers and ensuring the highest quality, most consistent and reliable source of calcium carbonate masterbatch.

Dong Luc™ is well regarded as a specialized, one-stop-shop for all plastic-related applications: Fiber (carpet, textiles, upholstery, Film (shopping bags, casting film, multilayer film), Blow Molding (medical & cosmetic containers, lubricant & paint containers), Extrusion Molding (sheet, pipe wire & cables), and Injection Molding (automotive, electronic, construction, housewares, furniture, toys). Contact us for an instant quote, or to schedule a free consultation with one of our U.S. based representatives.

Expanding Global Workforce

Dong Luc’s team of well-trained and highly skilled production, operations, and quality control engineers encompass an average of 10 years of professional experience. Together with a large staff of professional management and a global salesforce, we are capable of fulfilling our customers’ orders with the highest degree of reliability and efficiency. And we will do so with a relentless focus on safety and compliance.Investing in the Future

Since the beginning, Dong Luc™ has focused on investing in cutting edge technology, expanding our state-of-the-art factory, and improving production capacity to better serve both domestic and international market demand. Over the past decade, Dong Luc™ has developed systemized processes in order to operate continuously and produce more than 20,000 tons per year and growing. Our mission is to confidently surpass all of the requirements of our customers in terms of quality, quantity and price of our products.Strict Quality Control

Our continuous investment in modern production technology is due to our top priority of strict product quality standards. Before delivery, all of our products are subject to a strict inspection process. Dong Luc™ has an immense competitive advantage with our factory located nearby the most stable, abundant source of the highest quality CaCo3 filler material in the world.Cost-Saving Solutions

We aspire to establish ourselves as your exclusive and preferred partner of choice by striving to create the most value for our customers.

TICAL - TFS 190x

Enhances the physical properties of the product, increases the extrusion performance, reduces the specific heat of the resin, increases fire resistance, and increases adhesion when printing on solid material. Used with PP resins, TICAL – TFS 190x reduces product cost.

TICAL - TFC 2603

Increases the softness, as well as the toughness of film, increased adhesion and reduces product cost. Used in combination with resins: FC 9431G, L270, M9600, and LDPE 725 for coating on BOPP, PP, PE film, and paper coating.

TICAL - TFB 232x

Used with PP resins, TICAL – TFB 232x reduces product cost, increases adhesion when printing on solid material, increases fire resistance, reduces the specific heat of the resin, increases the extrusion performance, and enhances the physical properties of the product.

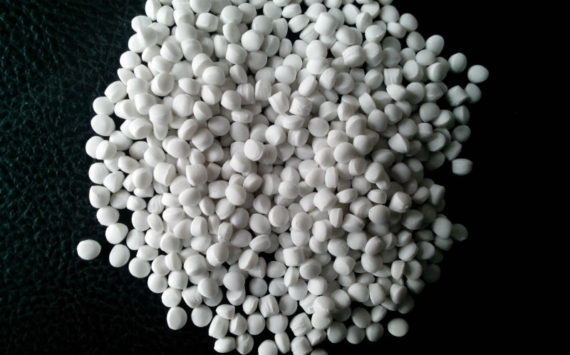

Calcium (Filler Masterbatch)

CaCO3 filler masterbatch cuts down production costs, while increases output, improves production conditions, as well as a number of physical and chemical properties of finished plastic products. We use advanced compounding technology and efficient proprietory formulations to achieve high consistency and quality of our calcium carbonate masterbatches.

Product Performance

Nano technology disperses ultrafine minerals, ensures high load ability for films and raffia applications with best in class tensile strength, machine throughputs, and price to performance ratio. Available with customization based on specific customer process applications such as FDA, UV stabilization, colortones, and a wide variety of resins: PP, PE, PS.

Cost Reduction

Reduce costs by replacing a part of the virgin polymer during extrusion, injection and blow molding with calcium carbonate. Popular for its low cost and characterized by its high chemical purity, high degree of whiteness, and low abrasiveness (improving the lifetime of machine parts), good disperability and approval for food utilization, making it well suitable for plastic packaging.

Dong Luc™ is Always Ahead

State-of-the-Art Manufacturing Capabilities

20000

Tons (Yearly Capacity)

5000

Factory Size (m2)

2010

Established Date

7

Closest Port (km)

Leveraged Growth: Expanding in the Global Economy

Vietnam’s manufacturing activity expanded at the fastest pace leading into the holiday season, says IHS Markit. The Nikkei Purchasing Managers’ Index, or PMI, climbed to 53.3. Moreover, the health of the sector strengthened for the twenty-second consecutive month. Among components, faster rises were recorded for output, new orders and employment, all linked to stronger customer demand in 2017. Dong Luc™ has recently opened up it’s first U.S. office in Seattle, WA, the nation’s fastest-growing big city. According to the Silicon Valley Competitiveness and Innovation Project’s (SVCIP) 2017 report, Seattle is also drawing the attention of big-name tech giants such as Amazon, eBay, Dropbox, Facebook and dozens of others who’ve established fast-growing engineering centers in the region in recent years.

Dong Luc™ Products

We incorporate our customers requirements and specifications, within our production standards, to manufacture the highest quality plastic additives at the most competitive prices.

TICAL – TFS 190x

ACCESSORIES FOR PLASTIC PP: TICAL – TFS 190x + Using TICAL – TFS 190x additives enhances the physical properties of the product, increases…

TICAL – TFC 2603

SUMMARY OF BOPP, PP, PE: TICAL – TFC 2603 + Use Tical TFC-2603 to increase the softness, as well as the…

TICAL – TFB 232x

PLASTIC ACCESSORIES USED FOR PE: TICAL – TFB 232x + Using TICAL – TFB 232x reduces product cost, increases adhesion when…